External Tooth Lock/Flat/Inner Tooth Lock/Spring Washer

Categories:

Keywords:

External Tooth Lock/Flat/Inner Tooth Lock/Spring Washer

PRODUCT DETAILS

| Washer Types | |||

|  |  |  |

| Flat A flat washer used to distribute load. Available in SAE, USS, and other patterns. | Fender An oversize flat washer used to further distribute load especially on soft materials. | Finishing A washer used to obtain a 'finished' look. Usually used with oval head screws. | Split Lock The most common style of washer used to prevent nuts and bolts from backing out. |

|  |  |  |

| External Tooth Lock A washer with external 'teeth' Used to prevent nuts and bolts from backing out. | Internal Tooth Lock A washer with internal 'teeth' Used to prevent nuts and bolts from backing out. | Square A square shaped washer. | Dock Dock washers have a larger outside diameter and are thicker than standard. |

|  | ||

| Ogee Thick, large diameter, cast iron washers with a curved or sculpted appearance. Typically used in dock and wood construction | Sealing A neoprene washer bonded to a metal backing. Used to seal out air/water or dampen noise and vibration. | ||

| Fastener material and coating |

|

| Fasteners come in a variety of materials. Selecting a material should be based on such considerations as environment (corrosive or temperature extremes), weight, magnetic properties, stresses, reusability, and expected life. Steel: Most fasteners are made from steel. Specifications cover a broad range of mechanical properties that are indicated by a bolt-head marking system that identifies the fastener by grade. For example, SAE grades 2, 5, and 8 are most often specified. Common steels are SAE 1010 (machine screws, carriage bolts, and other fasteners without critical strength requirements); SAE 1018, 1020, 1021 (bright cap screws, special items); SAE 1038 (high-strength bolts, studs, nuts, cap screws); SAE 1041, 1045, 1330, 1340 (special high-strength requirements), and SAE 1100 series (resulfurized -- usually for nuts). Aluminum: Aluminum alloys are the least costly, by volume, of all fastener metals. Aluminum fasteners are classified as hardenable and nonhardenable and weigh about one-third as much as steel. Some grades equal or even exceed the tensile strength of mild steel. The metal polishes to a high luster, has high thermal and electrical conductivity, is nonmagnetic, can be hardened by alloying, and has high corrosion resistance. Typical fastener alloys are 2024-T4 (cold-formed bolts, screws, rivets, machine-screw nuts), 2011-T3 (milled-from-bar nuts, screws, bolts), 1100 (cold-formed rivets), and 6061-T6 (nuts). Brass: This metal is worked easily into shape and has adequate strength. Tensile strength or hardness is improved by cold working. Some brasses have a greater tensile strength than mild carbon steel, along with a higher resistance to corrosion. The metal is nonmagnetic and takes a high luster. Copper: One of the most malleable of all metals, copper also has good corrosion resistance and the highest conductivity of all the nonprecious metals. Copper:One of the most malleable of all metals, copper also has good corrosion resistance and the highest conductivity of all the nonprecious metals. Copper is alloyed with silicon and manganese or aluminum for greater strength. Lead is added to give free-machining qualities. Typical alloys are high-silicon bronze, type A (hot-forged bolts, nuts; milled-from-bar bolts, nuts, setscrews); low-silicon bronze, type B (cold-formed bolts, nuts, rivets, screws); silicon-aluminum bronze (hot-forged products requiring special properties); and cupro-nickel, a copper-nickel alloy used for high strength and resistance to saltwater corrosion. Nickel: Fasteners can be made from commercially pure (99.4%) metal, Monel, or Inconel. They are used where toughness, immunity to discoloration and corrosion, and strength at high temperatures are desired. Pure nickel: Ideal for applications involving contamination, and strength retention at both high and subzero temperatures. Monel: Combines relative economy with adaptability to cold heading and roll threading. |

| Inconel: Excellent for fasteners that must retain high strength and oxidation resistance at temperatures up to 1,600°F. Stainless steels: Fasteners of this metal are used where corrosion, temperature, and strength are problems. They also produce a mirrorlike finish. There are three basic types: Martensitic: Magnetic and hardenable. Common fastener alloys are Types 410, 416, and 431. Ferritic: Magnetic and not hardenable by heat. Can be cold worked with reasonably good results. Used for economic reasons, and where corrosion-resistance requirements are not too severe. Best fastener alloy types are 430 and 430F. Austenitic: Nonhardenable, nonmagnetic, and offers the greatest degree of corrosion resistance. Typical alloys are 18-8 and 300 series. Titanium:Fasteners made from this material are used chiefly on aircraft. Titanium has excellent corrosion resistance and good high-temperature performance. These fasteners are most commonly used in joints loaded in shear but are also used in tension-loaded joints. Beryllium:Exceptionally lightweight, beryllium fasteners are about 40% as heavy as titanium. Brittleness is a limitation to widespread use. Beryllium bolts are used primarily for applications where the shear requirement is at least 60 ksi. |

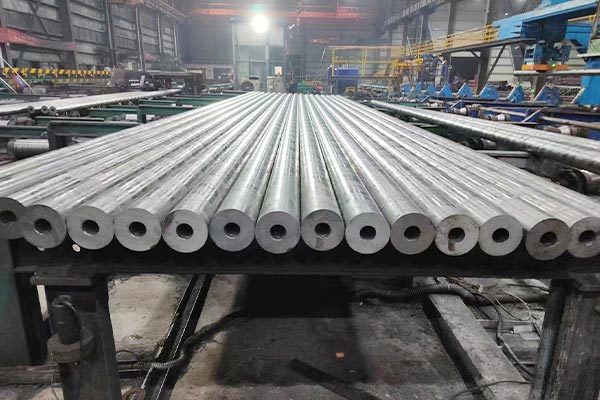

FACTORY APPEARANCE

Our extensive product portfolio is designed to meet diverse industrial needs, including: hot rolled steel plates, cold rolled steel plates, seamless and welded steel pipes, galvanized steel and colour coated products, stainless steel sheets and coils, aluminium and nickel products.

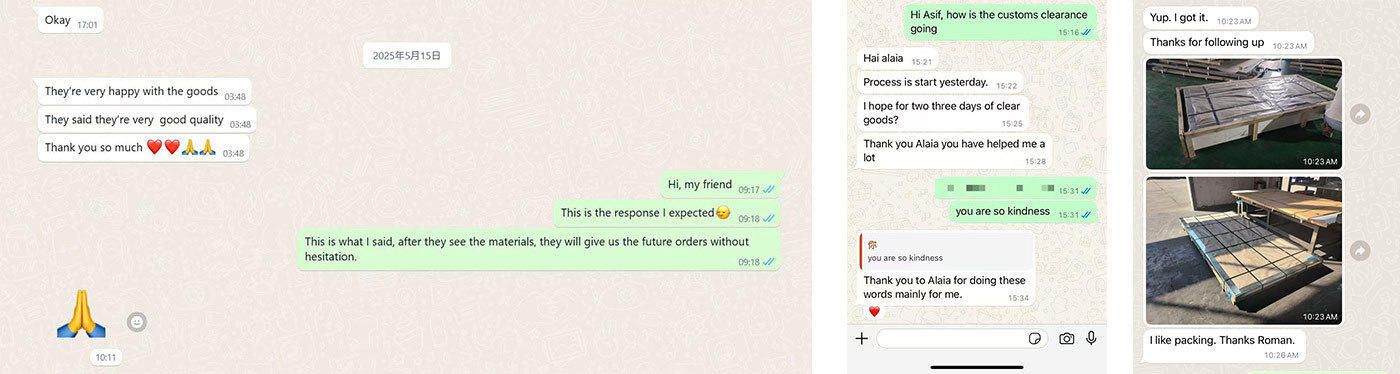

PACKING AND DELIVERY

CUSTOMER FEEDBACK

We welcome partners from all over the world and look forward to building long-term business relationships based on trust, quality, and innovation. We're here to grow your business.

CUSTOMER VISIT

We are committed to building long-term partnerships by providing reliable products and exceptional service to our global clientele.

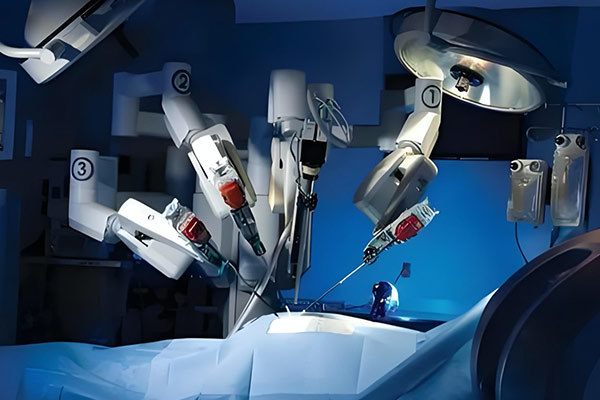

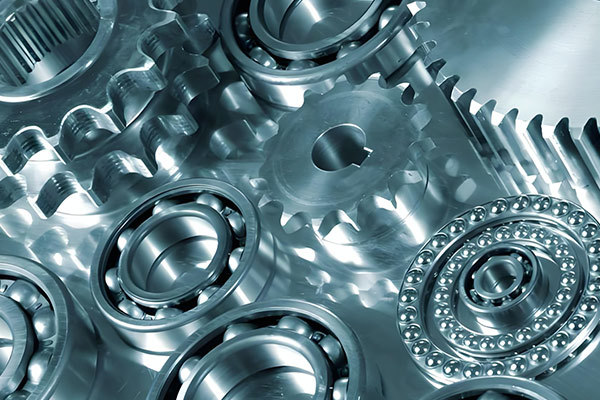

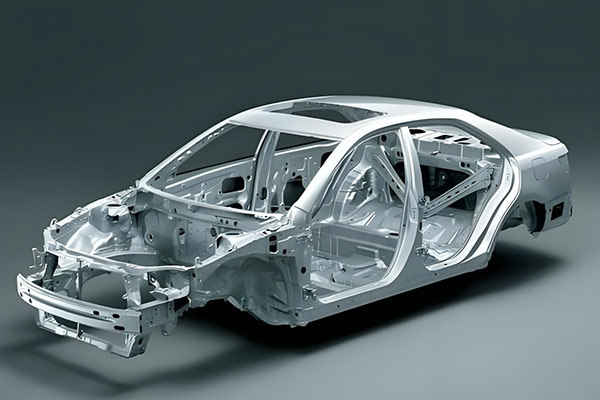

APPLICATION AREAS

Large venues

Mechanical processing

Steel smelting

Tall Buildings

Gear machining

Automobile manufacturing

FAQ

Q: How can lget your quotation as soon as possible?

Q: Do you provide after-sale service?

Q: Do you provide samples?

Q: How long is your delivery time?

Q: Do you have a quality inspection system?

Q: Are you a manufacturer or a trading company?

GET A FREE QUOTE

If you have any needs, we can tailor professional steel solutions for you.

Customer Reviews

After comparing several companies, I finally chose this one, and I was not disappointed! The steel surface is smooth and flawless, the weight is sufficient, the customs declaration information is clear and standardized, and the cooperation experience is perfect!

Customer Reviews

This batch of steel exported to Europe was highly praised by the customer during the factory inspection. He said that the material is uniform and the processing performance is good. He has listed us as a preferred supplier. Thank you!

Customer Reviews

The customer service is very professional and familiar with the foreign trade process. They assist throughout the process from quotation to document preparation. Communication is very worry-free. The steel itself is also excellent and very cost-effective!

WHY CHOOSE US

RELIABLE QUALITY

In accordance with international standards, it has strict control and stable performance, and can meet the high requirements of multiple scenarios.

COMPLETE SPECIFICATIONS

A variety of materials and models are available to suit multiple industries, reducing purchases from multiple parties.

PRICE COMPETITIVENESS

With the advantages of scale and supply chain, it has high cost performance and reduces procurement costs.

STABLE SUPPLY

Mature production logistics ensure long-term supply and on-time delivery.

RELATED PRODUCTS