PRODUCTS

CONTACT US

No matter what industry you are in, such as construction, manufacturing, energy or logistics, we can tailor professional steel solutions for you.

Type 316 stainless steel is an austenitic grade with added molybdenum. The alloy offers improved corrosion resistance when compared with Type 304, particularly in chloride environments.

Grade 304 is the most commonly used stainless steel. It is an austenitic, corrosion-resistant steel with excellent strength, toughness, fabrication characteristics and weldability. The low carbon version, 304L, may be required for full corrosion resistance when thicker sections are welded.

AISI 430(UNS S43000) stainless steel sheet

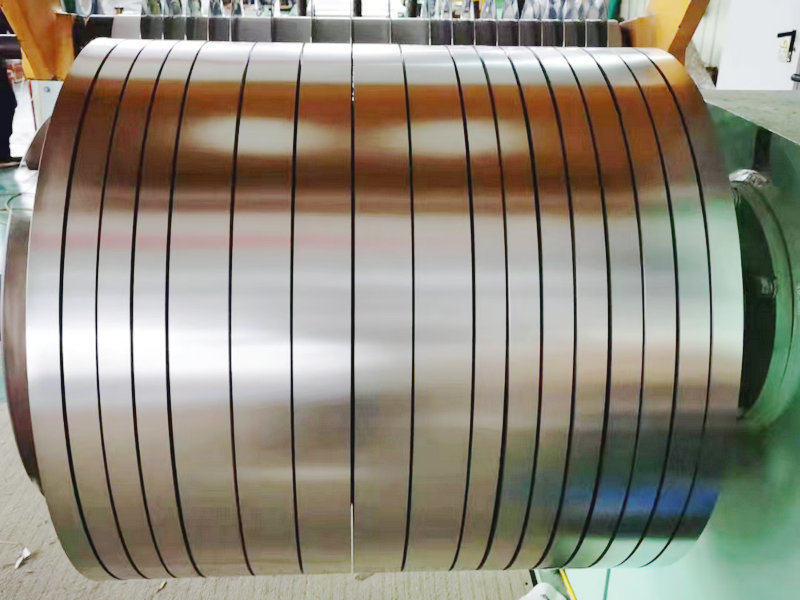

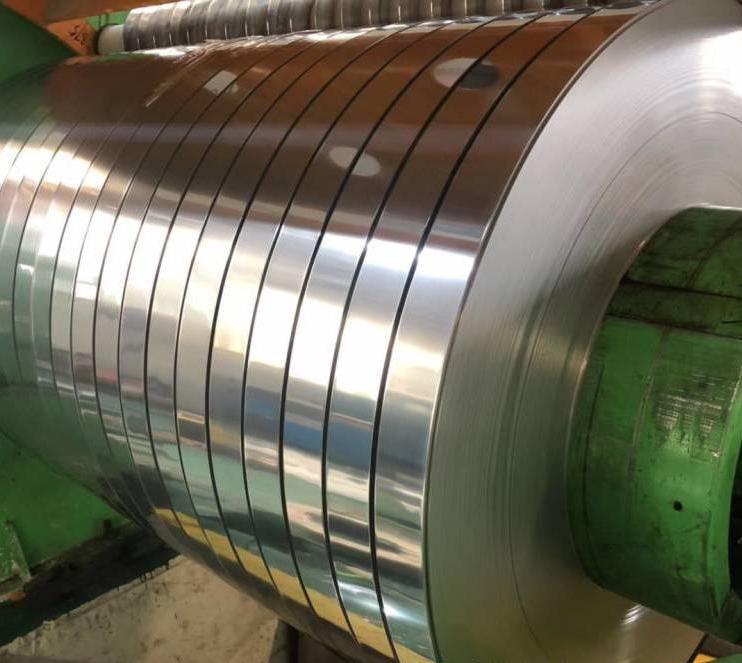

430 stainless steel strip is a ferritic stainless steel material with good corrosion resistance, formability and oxidation resistance, but it does not contain nickel, so it is low in cost and has no obvious magnetic weakening. It is often used in occasions with moderate corrosion resistance requirements but cost-sensitive conditions, such as kitchenware, home appliances, decoration, automotive exhaust systems, etc.

20Cr17Ni2 stainless steel sheet

20Cr17Ni2 is a domestically produced high-chromium-nickel stainless steel with excellent corrosion resistance, oxidation resistance and mechanical properties. It is often used in the manufacture of parts with high corrosion resistance, such as chemical equipment, heat-resistant containers, food processing equipment, precision instruments, etc.

Cr18Ni9Ti/AISI-321 stainless steel sheet

321 stainless steel plate is an austenitic stainless steel belonging to the 18-8 series (i.e. 304 series) modified steel. Titanium (Ti) is added to 304 to improve its resistance to intergranular corrosion. It is particularly suitable for equipment or structures working in high temperature environments (such as 600~900℃).

Type 316L stainless steel in a molybdenum bearing austenitic. It is more resistant to general corrosion and pitting than conventional nickel chromium stainless steels such as 302-304. It has the following characteristics:Higher creep resistance,Excellent formability,Rupture and tensile strength at high temperatures,Corrosion and pitting resistance.

310S stainless steel sheets is similar to stainless steel 310 apart from a lower content of carbon that reduces carbideprecipitation and enhances weldability. The soaring nickel and chromium contents of ss 310s plates offer similar corrosionresistance, higher resistance to oxidation and the holding of a superior portion of room temp potency than the usual austeniticsteel such as S304.

Stainless steel 310/310S is an austenitic heat resistant alloy with excellent resistance to oxidation under mildly cyclic conditions through 2000°F. Stainless 310 is often used at cryogenic temperatures, with excellent toughness to -450°F, and low magnetic permeability.

309 stainless steel has a higher corrosion resistance and strength compared to 304 stainless steel. This product is versatile and known for its high heat treatment capabilities.