PRODUCTS

CONTACT US

No matter what industry you are in, such as construction, manufacturing, energy or logistics, we can tailor professional steel solutions for you.

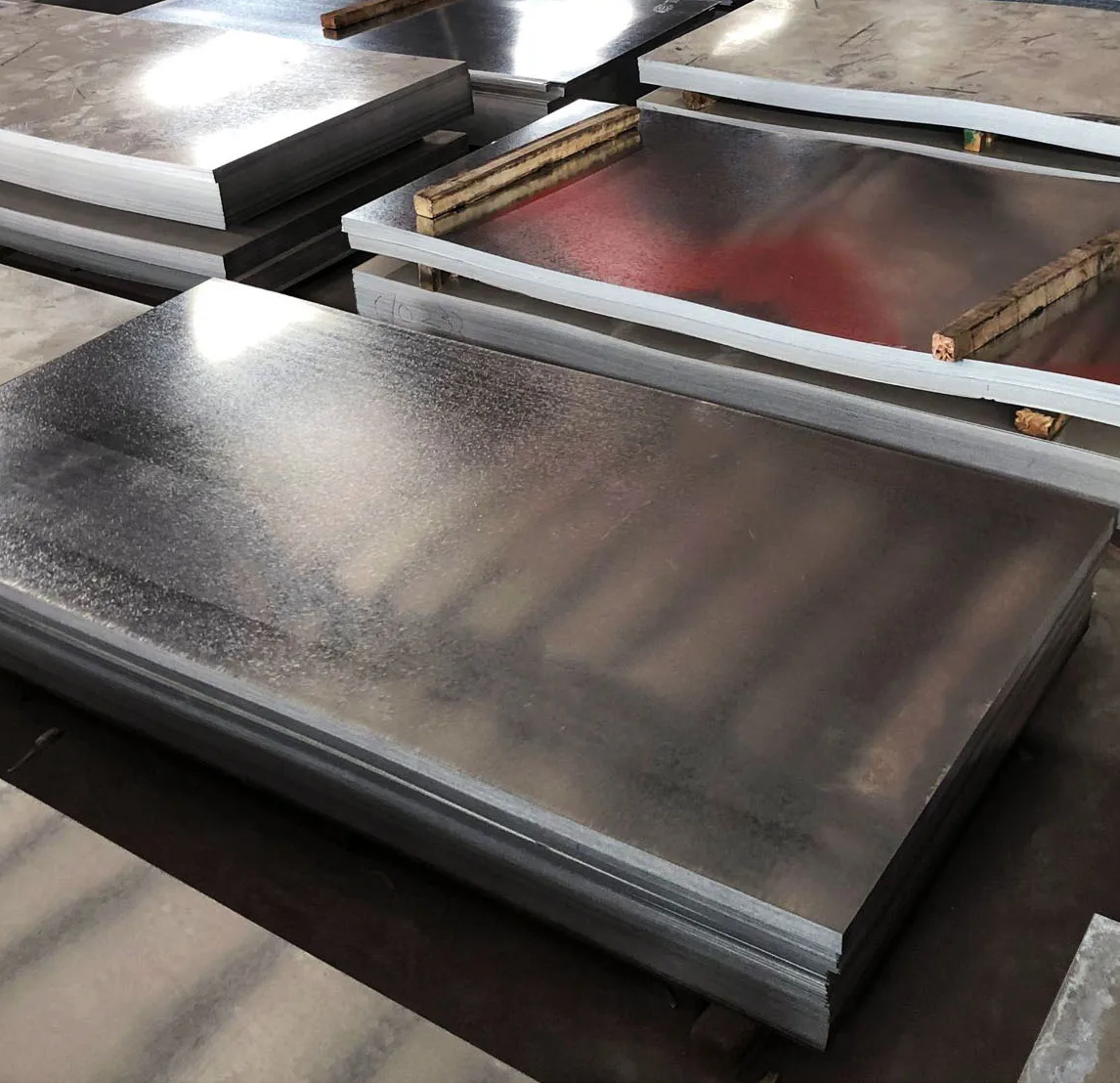

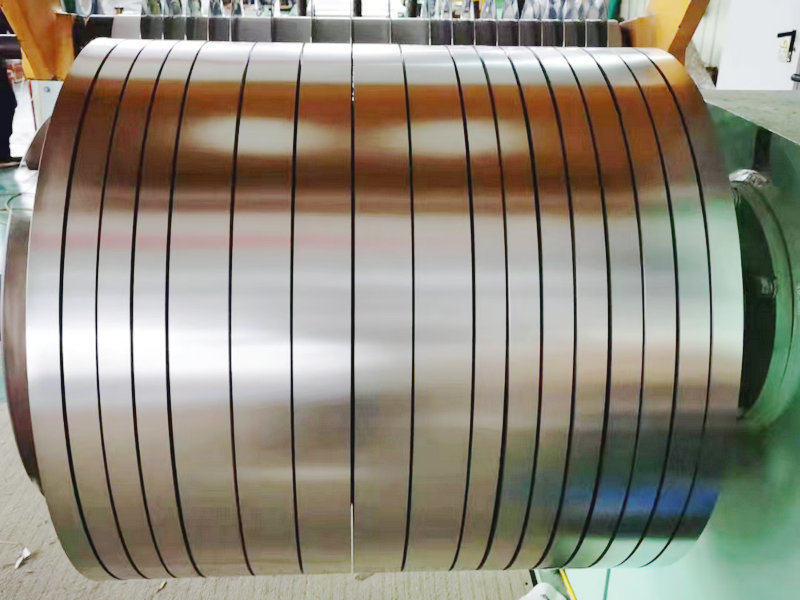

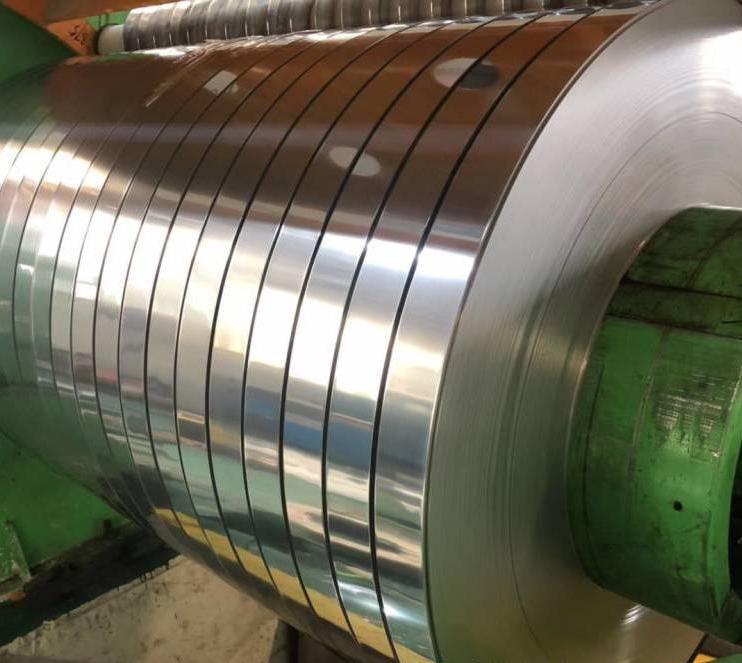

Galvanized steel sheet is standard steel that is coated in zinc to provide enhanced corrosion resistance. The galvanized protective coating protects the iron steel substrate from corrosion due to moisture, saturated environmental conditions, or ambient humidity.

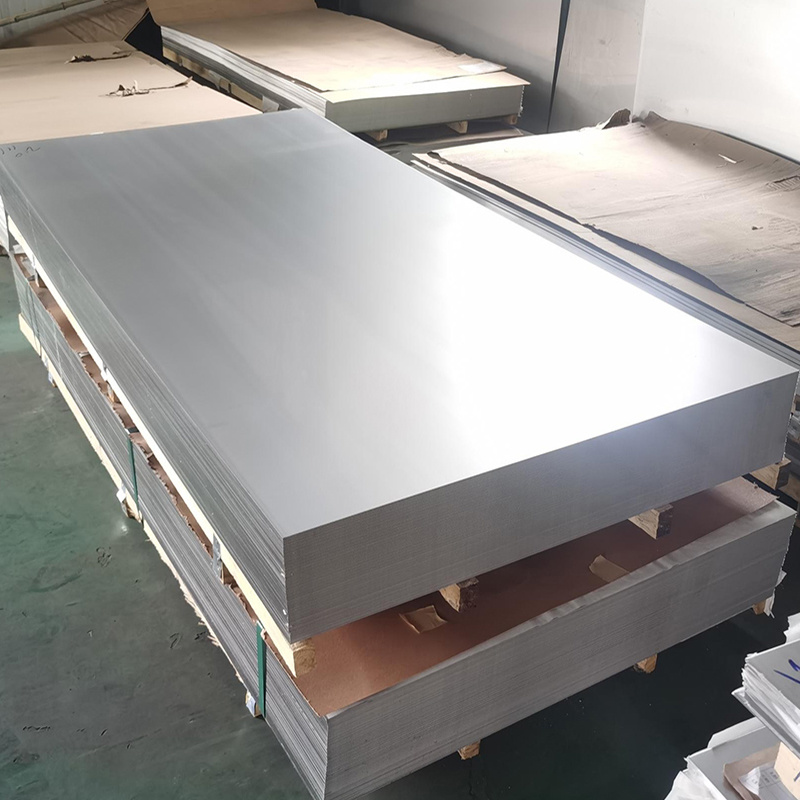

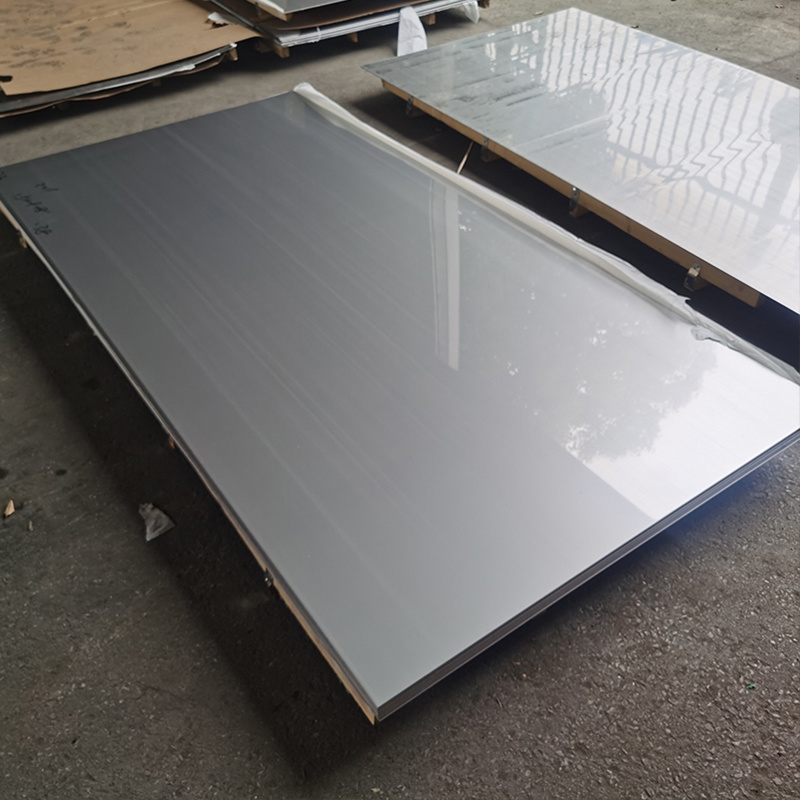

Type 316 stainless steel is an austenitic grade with added molybdenum. The alloy offers improved corrosion resistance when compared with Type 304, particularly in chloride environments.

Grade 304 is the most commonly used stainless steel. It is an austenitic, corrosion-resistant steel with excellent strength, toughness, fabrication characteristics and weldability. The low carbon version, 304L, may be required for full corrosion resistance when thicker sections are welded.

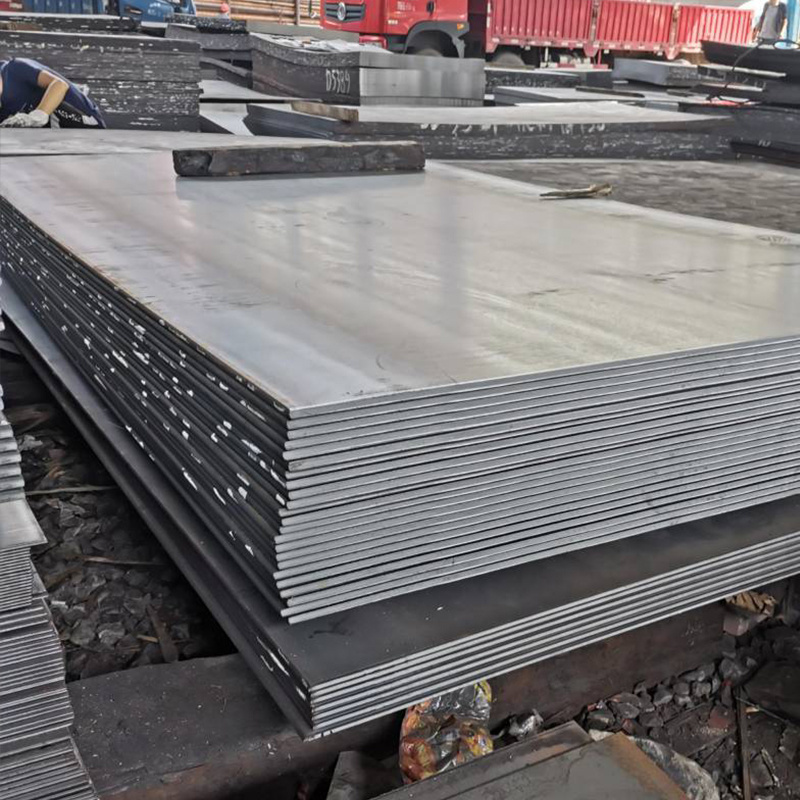

Carbon structural steel plate is an industrial plate based on carbon steel and is widely used in construction, machinery manufacturing and other fields.

AISI 430(UNS S43000) stainless steel sheet

430 stainless steel strip is a ferritic stainless steel material with good corrosion resistance, formability and oxidation resistance, but it does not contain nickel, so it is low in cost and has no obvious magnetic weakening. It is often used in occasions with moderate corrosion resistance requirements but cost-sensitive conditions, such as kitchenware, home appliances, decoration, automotive exhaust systems, etc.

20Cr17Ni2 stainless steel sheet

20Cr17Ni2 is a domestically produced high-chromium-nickel stainless steel with excellent corrosion resistance, oxidation resistance and mechanical properties. It is often used in the manufacture of parts with high corrosion resistance, such as chemical equipment, heat-resistant containers, food processing equipment, precision instruments, etc.

Cr18Ni9Ti/AISI-321 stainless steel sheet

321 stainless steel plate is an austenitic stainless steel belonging to the 18-8 series (i.e. 304 series) modified steel. Titanium (Ti) is added to 304 to improve its resistance to intergranular corrosion. It is particularly suitable for equipment or structures working in high temperature environments (such as 600~900℃).

Inconel alloys are high-performance nickel/chromium superalloys developed for high temperatures, corrosive environments, and oxidation resistance. They are used in the harshest environments such as: in chemical processing reaction chambers/valves, polymer granule manufacture, military applications, gas turbine components, oil fields, and high-grade marine applications.

Inconel alloys include:

Inconel 600: solid solution reinforcement

Inconel601

Inconel 625: Acid resistance, good weldability. The LCF version is commonly used for bellows.

Inconel 690: Low cobalt content and low resistivity for nuclear applications

Inconel 713C: Precipitation-hardened nickel-chromium base cast alloy Inconel

718: Gamma double prime reinforced with good weldability

Inconel 751: Increased aluminum content to increase fracture strength in the 1600 °F range

Inconel 792: Increased aluminum content to improve high-temperature corrosion performance, especially for gas turbines

Inconel 939: Gamma prime reinforced to improve weldability

Incoloy alloys are known for their iron content. Nickel, iron, and chromium are the main and vital ingredients for Incoloy alloys.