PRODUCTS

CONTACT US

No matter what industry you are in, such as construction, manufacturing, energy or logistics, we can tailor professional steel solutions for you.

D406A = A high-strength, temperable, corrosion-resistant domestically produced martensitic stainless steel for aviation applications. Equivalent to AISI 431 / 20Cr17Ni2, it is suitable for aviation structural parts requiring high strength and reliability.

Maraging 250 (18Ni-250) is a typical maraging steel with high strength, good toughness and excellent dimensional stability. It is widely used in aerospace, military, precision molds and racing car structural parts.

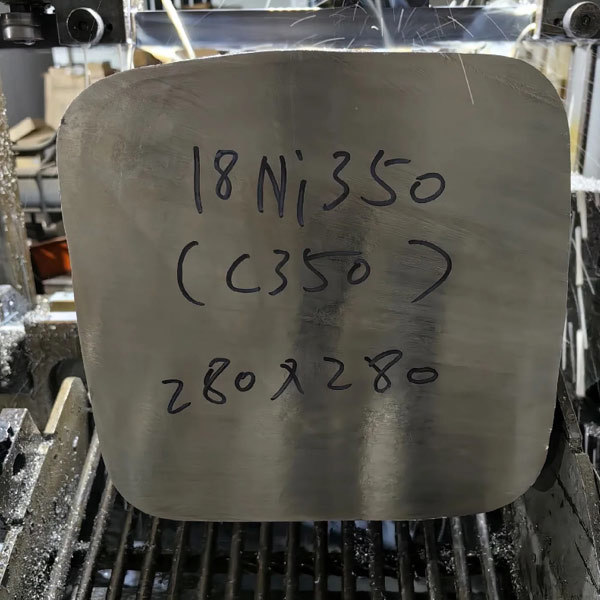

18Ni350 (Maraging 350 / C350) is an ultra-high-strength maraging steel, the strongest grade among the 18% nickel series maraging steels. It exhibits excellent tensile strength, dimensional stability, and weldability, making it primarily used in applications requiring extreme strength, such as aerospace, military, molds, and racing.

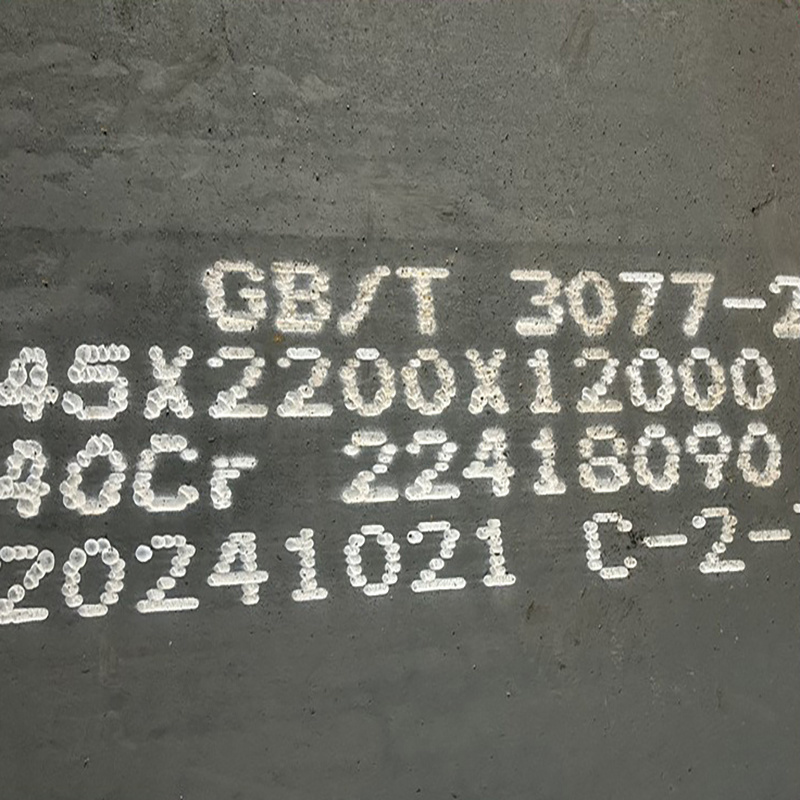

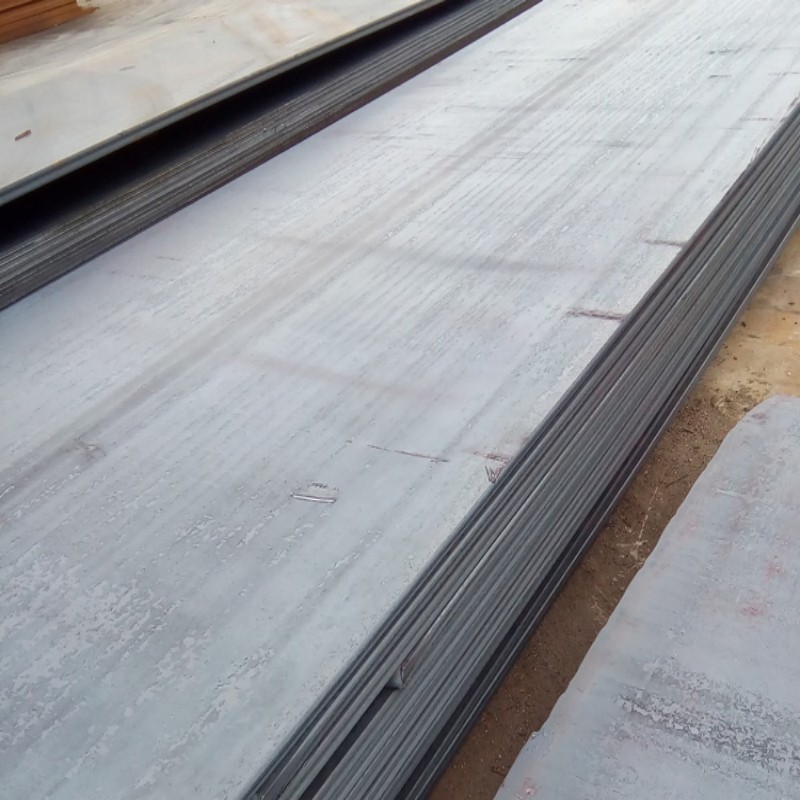

40Cr (GB/T 3077) is a versatile chromium alloy steel renowned for its exceptional strength, wear resistance, and cost-effectiveness. Widely used in automotive, machinery, and tooling industries, this medium-carbon steel delivers superior performance for critical components.

40CrNiMoA (GB/T 3077) is a premium chromium-nickel-molybdenum alloy steel engineered for extreme performance in mission-critical components. With tensile strength reaching 1800 MPa, this advanced material delivers unmatched strength-to-toughness balance.

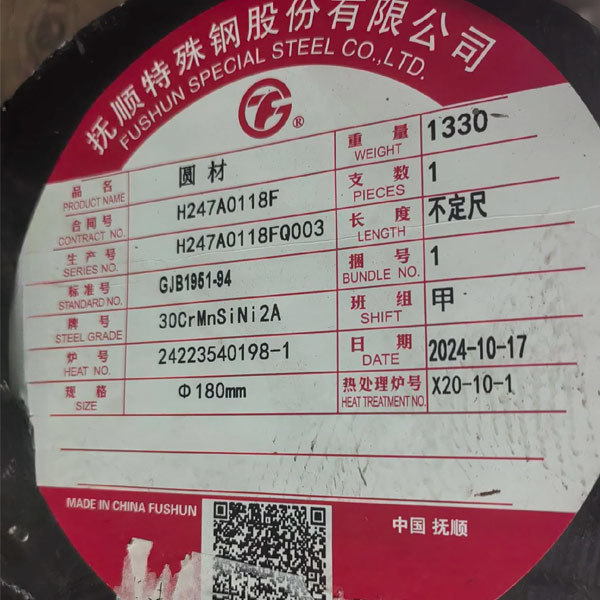

35CrMnSiA is a premium chromium-manganese-silicon alloy steel (GB/T 3077 standard) engineered for extreme performance in critical load-bearing applications. It has tensile strength reaching 1600-1800 MPa, making it ideal for high-performance applications.

35CrMnMo is a premium chromium-manganese-molybdenum alloy steel (GB/T 3077) engineered for extreme mechanical stress. With exceptional strength (up to 1500 MPa), toughness, and wear resistance.

20CrMnTi (GB/T 3077) is a chromium-manganese-titanium alloy steel widely used in automotive gears, transmission parts, and heavy-duty machinery components. Known for its excellent hardenability, wear resistance, and toughness, this steel is ideal for carburizing (case hardening) to achieve a hard surface (58-62 HRC) while maintaining a ductile core.

17-4ph (ASTM A564 / A693 / A705 0Cr17Ni4Cu4Nb(SUS 630)

17-4PH is a precipitation-hardening martensitic stainless steel. Its full name is:17% Cr + 4% Ni + Cu + Nb precipitation-hardening stainless steel